Lowest Price for Polypropylene Bulk Bags - The PP Woven Jumbo Bag/Big Sack/Super Bag – Prosperousagro

Lowest Price for Polypropylene Bulk Bags - The PP Woven Jumbo Bag/Big Sack/Super Bag – Prosperousagro Detail:

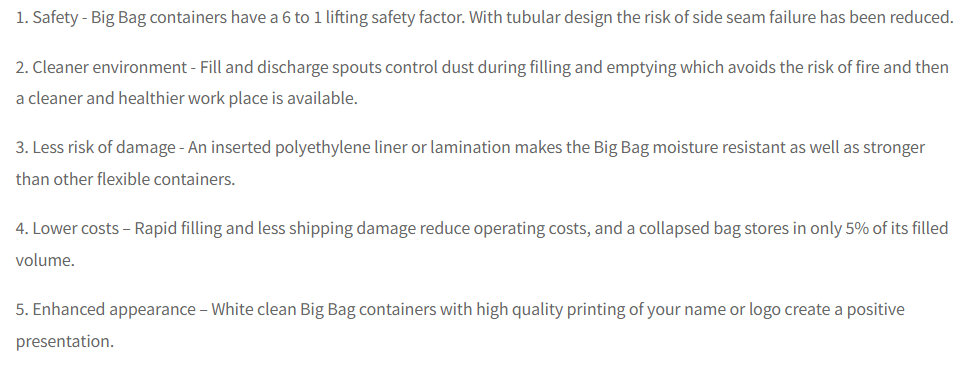

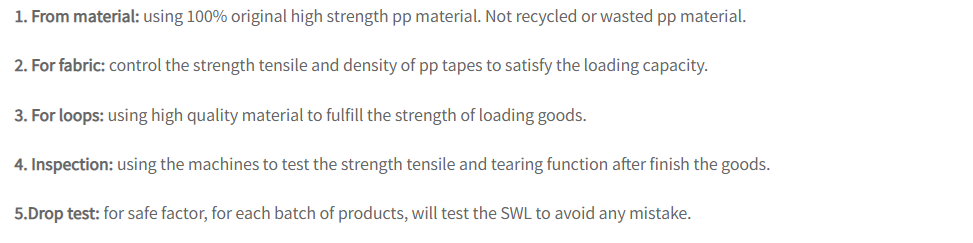

The pp woven jumbo bag/big sack/super bag, it was made by 100% original polypropylene, through extruding, drawing the pp tape, weaving the tapes to circular fabric. then sewing different parts to the whole U type or C circle type. they are widely used as the packages of bulk cement, construction, chemical resin.

Detailed specification of 500kg to 2000kg FIBC big bag, jumbo sack, bulk container bag, ton bag:

| No. | Item | Specification |

| 1 | Size | 85cm*85cm*90cm/90cm*90cm*100cm or customized |

| 2 | Body construction | 4-panel/U panel/Circular panel/Tubular panel/rectangular type |

| 3 | Top | Open mouth/skirt mouth/ filling spout |

| 4 | Bottom | Flat /discharge spout |

| 5 | Loop type | side seamed /cross corner/double stevedore with 2-4 belts |

| 6 | Printing type | one or two side with 1-3 color off set color |

| 7 | Optional parts | document pouch/label/rings/PE liner |

| 8 | SWL | 5:1/3:1/6:1 |

| 9 | Loading capacity | 500kg to 3000kg |

| 10 | Color | white, yellow, blue or customized |

| 11 | Fabric weight | 100g/m2 to 240g/m2 |

| 12 | Fabric treatment | anti-slip or laminated or plain |

| 13 | Rope type | 1 or 2 around the body or customized |

| 14 | Application | For packing the cement, sand, resin, wood waste, grain, powder, |

| chemical resin, construction material, mine, coal.. | ||

| 15 | Inside liner | 60g/m2 to 80g/m2 PE liner |

| 16 | Characteristics | moisture-proof, conductive, reinforcement, dust-proof |

| 17 | Material | 100% original pp |

| 18 | Sewing type | Plain/chain/chain lock with optional soft-proof |

| 19 | Package | about 100kg for one bale |

| 20 | Delivery Time | within 25-30 days for one 40H container |

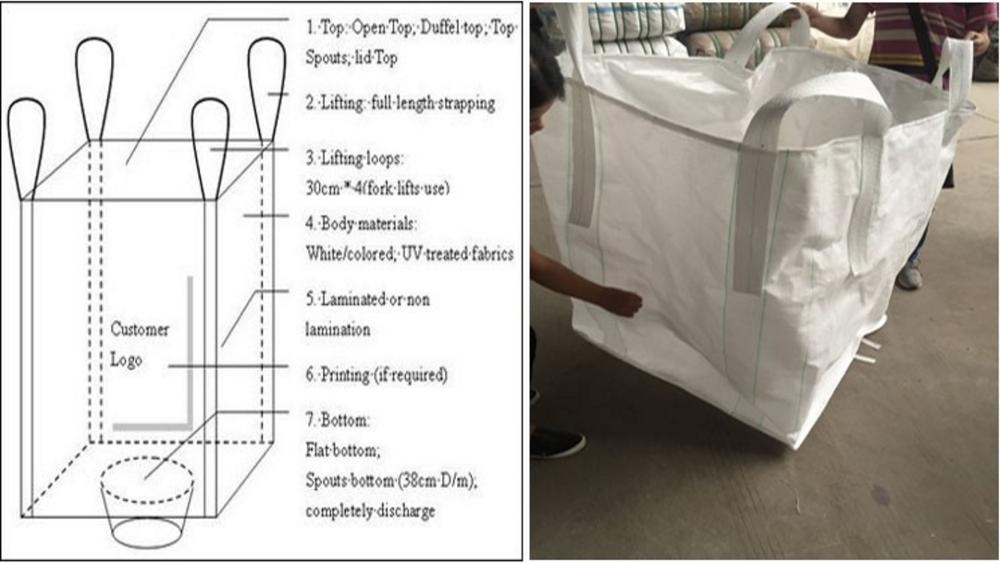

The tops of big bags: open mouth or skirt(duffle)or filling spout

The bottom of the big bags: flat bottom or discharge spout

The loops of the big bags: cross corner or side seamed

The other options: with PE liner or labels or document pouch

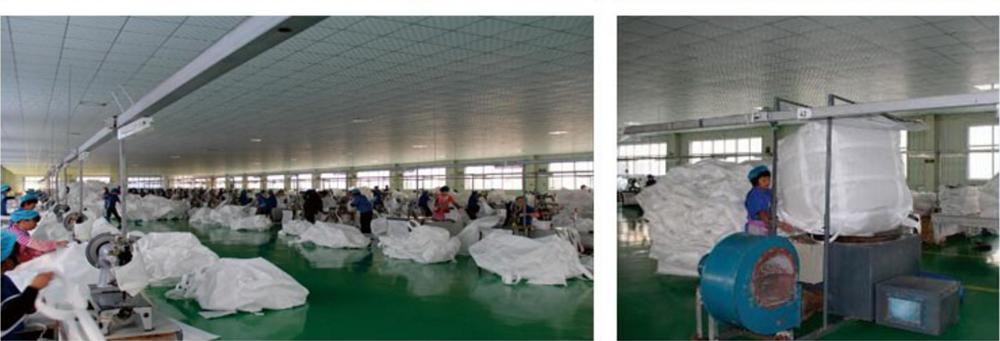

Production process of 500kg to 2000kg FIBC big bag, jumbo sack, bulk container bag, ton bag The following is the whole process to making the super sack/big sack/jumbo bag/woven pp bulk bag:

Extruding PP particle———Drawing and cutting PP film——-thread the PP tapes——-Weaving pp tapes to tubular fabric——-Printing the body———sewing top/bottom parts and loops and other parts——–Inspecting the strength tensile-package

1. Food Area: sugar, salt, flour, starch.

2. Agriculture Area: grains, rice, wheat, corn, seeds, flour, coffee Beans, soybeans

3. Feed: pet food, pet litter, bird seed, grass seed, animal feed.

4. Chemicals: fertilizer, chemical materials, plastic resin.

5. Construction material: sand, cement, powder.

Product detail pictures:

Related Product Guide:

Cooperation

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for Lowest Price for Polypropylene Bulk Bags - The PP Woven Jumbo Bag/Big Sack/Super Bag – Prosperousagro , The product will supply to all over the world, such as: Bolivia, Botswana, Tunisia, To create more creative products, maintain high-quality products and update not only our products but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer and to grow stronger together. To be the real winner, starts here!

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!