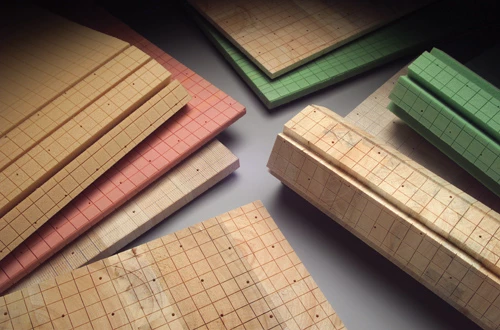

Good Quality Balsa Strips from Ecuador

Ochroma Pyramidale, commonly known as the balsa tree, is a large, fast growing tree native to the Americas. It is the sole member of the genus Ochroma. The name balsa comes from the Spanish word for "raft".

A deciduous angiosperm, Ochroma pyramidale can grow up to 30m tall, and is classified as a hardwood despite the wood itself being very soft;t is the softest commercial hardwood and is widely used because it is light weight.

Balsa Strips can be glued into balsa blocks used in wind turbine blades as the core structural materials.

Balsa wood is often used as a core material in composites; for example, the blades of many wind turbines are partly of balsa. End-grain balsa is an attractive core material for wind blades because it is comparatively inexpensive and dense enough to offer greater strength than foams, a trait particularly useful in the highly stressed cylindrical root section of the blade. Balsa wood sheet stock is cut to specified dimensions, scored or kerfed (along both length and width, as shown, for compound curves) and then labeled and assembled by core suppliers into kits.

Only 40% of the volume of a piece of balsa is a solid substance. The reason why it can stand tall and strong in the jungle is that it is actually filled with a lot of water, like a tire full of air. When balsa is processed, the lumber is placed in a kiln and is kept there for two weeks to remove all excess water. Wind turbine blades are made from balsa wood which is sandwiched between two bits of fiberglass. For commercial production, the wood is kiln-dried for about two weeks, leaving the cells hollow and empty. The large volume-to-surface ratio of the resulting thin-walled, empty cells gives the dried wood a large strength-to-weight ratio because the cells are mostly air.